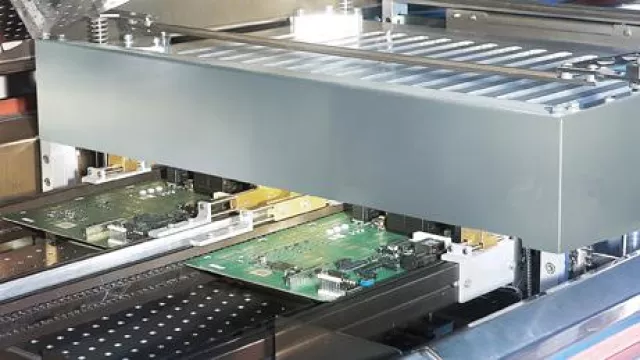

(openPR) Energy-efficient, low-maintenance and void-free – with new, diverse options for the Reflow Soldering System VisionXP+, Rehm Thermal Systems offers innovative solutions for reflow soldering with convection. At this year's SMT trade fair in Nuremberg, the vacuum option generated a particularly high level of interest among national and international customers. Whereas the usual method up to now was to remove voids and pores at the soldering point with an external vacuum module, this is integrated in the VisionXP+ Vac. Gas inclusions can be reliably eliminated inline during the convection soldering process. Outstanding soldering is possible as a result, without interrupting the work process – a clever two-in-one solution! The efficient energy concept also ensures sustainable production.

"There is very great interest in flexible and reliable soldering systems that work in an energy-efficient manner and keep operating costs low. Rehm has already adopted this new approach. VisionXP+ convinces in particular on the international market with the combinable modules and energy management. This was confirmed by the high demand at the SMT trade fair in Nuremberg and particularly also by our strong increase in customers in the US and in the European and Asian regions," says Rehm Chief Customer Officer Michael Hanke.

Energy-saving concept of VisionXP+

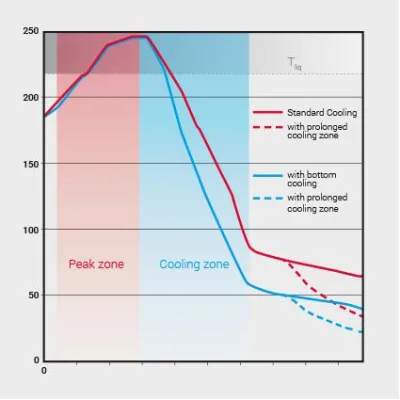

VisionXP+ scores with clear benefits. An even more efficient transmission of heat and fewer emissions facilitate environmentally friendly production and reduce operating costs. Optimum insulation and the innovative gas regulation ensure reduced loss of heat and a lower consumption of nitrogen during the processes. In all further developments of the systems, Rehm Thermal Systems focuses at all times on the efficient handling of materials and resources. With VisionXP+, customers can save up to 20 % in energy during their production processes and generate an average of 10 tons less CO2 per year.

Vacuum option enables void-free soldering points

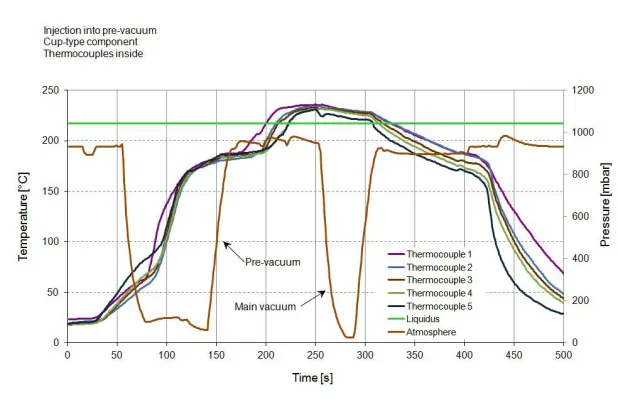

The new vacuum model makes void-free convection soldering possible in just one process. VisionXP+ Vac already reliably removes pores, gas inclusions and voids during the soldering process, whilst the solder is still in an ideally molten state. With a negative pressure of up to 2 mbar, void rates of below 2 % are possible. Pressure and speed can be regulated individually. This integrated solution enables a time-efficient and stable production process. Costly reworking of the sub-assembly by an external vacuum system is no longer necessary as the work pieces are handed over directly to the vacuum process from the peak zones.

Residue management – efficient through the use of pyrolyses

As a further innovative feature, VisionXP+ from Rehm Thermal Systems is optionally equipped with a second pyrolysis. The pyrolyses are installed under the inlet and outlet area. This makes effective residue management possible. Material residues are reliably removed from the system. The first pyrolysis removes the process gas from the pre-heating zones, the second the gas from the peak zones. The degree of cleaning is substantially higher and the process chamber remains clean and dry. With an annual granulate change, the maintenance effort, however, is reduced to a minimum.